High Strength and Toughness: Through high-temperature heating and forging processes, the internal structure of the

steel ball becomes denser. Defects such as as-cast porosity generated during the smelting of the metal are eliminated, and the micro-structure is optimized. At the same time, the complete metal flow lines are preserved, giving it extremely high strength and toughness, enabling it to withstand large impacts and pressures.

Uniform Structure: During the forging process, the internal stress of the metal is effectively released, and the structure becomes more uniform. This improves the wear resistance and corrosion resistance of the steel ball and reduces local wear and corrosion problems caused by uneven structure.

Precise Dimensions and Shape: The forging process can precisely control the dimensions and shape of the steel ball, reducing errors in the processing. It improves the precision of the product and meets the strict requirements of various equipment for the dimensions and shape of the steel ball.

Good Anti-fatigue Performance: Due to its excellent structure, the forged steel ball can better resist fatigue failure when subjected to cyclic loads, extending its service life. It is suitable for scenarios that require long-term stable operation.

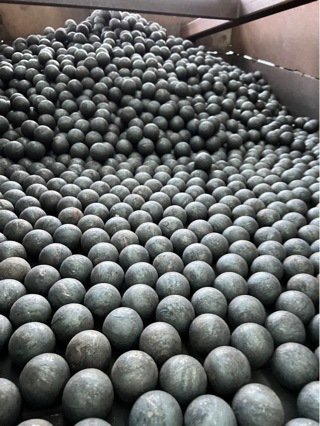

Good Surface Quality: The surface of the forged steel ball is relatively smooth, without defects such as pores and blowholes. It is not only aesthetically pleasing but also can reduce the frictional resistance during use, lowering energy consumption. At the same time, it also helps to improve the fitting accuracy between the steel ball and other components.

High Material Utilization Rate: The utilization rate of the steel ingot during the forging process is relatively high, reducing material waste. Compared with some other processing methods, it reduces the production cost to a certain extent.

Low Processing Cost: Although the initial investment in the forging process is relatively high, due to its high production efficiency and high material utilization rate, in the long run, the processing cost of forged steel balls is relatively low, which has good economic benefits.